REPAIRING DARLEY ABBEY NORTH MILL

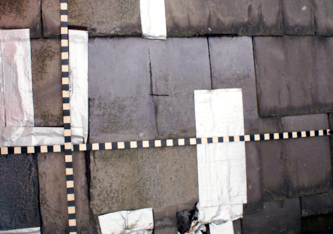

Fire-proof slating Darley Abbey Mills. The underside with the torching removed

The mill had stopped the original activities in the late 20th century. From then very little maintenance had been carried out on the roofs. Just temporary repairs to stop leaks with flashband. We were asked to carry out some emergency repairs to some of the mill buildings. Eventually we repaired the whole site.

This is how the fire-proof slating was repaired on the North Mill. In the original construction the slates were fixed with copper wire through their top edges which was wrapped around metal laths. These laths are fixed to slightly concave cast iron rafters which helps the slates lie tightly against each other. The underside was fully torched. At the eaves there are large cast iron gutters hidden behind brick parapets.

As usual with roofing we had to remove some of the historic fabric such as the torching but each of the original features was re-instated so that the final repair is as authentic as is possible.

Most of the slates were sound even though they had been on the roof for nearly 180 years but some were cracked or broken probably caused when the flashband repairs were done. These were removed and replaced with new slates from Welsh Slate’s Penrhyn quarry.

The first job was to remove the lime mortar torching. This meant having one person on the outside tapping the damaged slate so the one on the inside knew he was in the right place.

Once this was done and working in twos the slates were repositioned and wired in place. The copper wires were threaded through a hole near the top edge of the slate, over the metal laths and were then twisted to secure them. There were two wires in each slate. It was quite difficult to judge how much to twist them so that the slate was secure - twist too much and the wire would snap.

Once an area of slating was replaced it was ready to torch. This was done exactly as originally. Mortar was pointed onto the top of the lower slate without forcing it down between them. You can see this in the video - after the main torching is removed.

15/9/12

Temporary flashband repairs Scale 25mm

Removing the 33 inch long slates

Inserting the copper wire through the slate’s head

Twisting the wire to secure the slate

Reinstating the lime mortar torching

Pointing the slate’s head

Links to other fire proof roofs