DITHERINGTON FLAX MILL

History of the Mill *

Ditherington Mill is the world’s first completely iron-framed building. The factory was built in 1796-1797 for Marshall, Benyon and the architect Charles Bage to spin flax which could then be woven into linen. It continued as a flax mill until 1886 and in 1897, the buildings were adapted as a maltings by William Jones & Sons. With a brief interruption during World War II, they continued to serve as a maltings until 1987 since when they have been empty. It is the ancestor of all iron-framed and steel-framed structures, including modern skyscrapers.

Marshall and the Benyon Brothers had experienced a devastating fire at one of their mills in Water Lane, Leeds on 13 February 1796. The cost was estimated at £10,000, only half of which was met by insurance. Undoubtedly, they wanted a different mode of construction for a new fire-proof building. The mill in Shrewsbury provided this opportunity.

Charles Bage had a great understanding of the structural properties of iron. This is revealed in various records, including his correspondence with the factory master, William Strutt in Derbyshire who shared his interest in iron construction. Bage’s friendship with William Strutt (1756-1830) of Belper in Derbyshire extended his knowledge of the use of iron in mill construction. In 1792-1793, Strutt had built a cotton factory in Derby which used cast and wrought iron as integral parts of its brick and wood structure. He expanded the use of iron to build the six-storey West Mill in Belper in 1795. Bage’s correspondence with Strutt, dating from the early 19th century provides an insight into his understanding of the structural properties of the metal and other subjects such as furnaces, gas lighting and bleaching flax. Bage recognised his debt to Strutt “for teaching us to make buildings fireproof.”

Ditherington Flax Mill: a new beginning for an icon of industry >

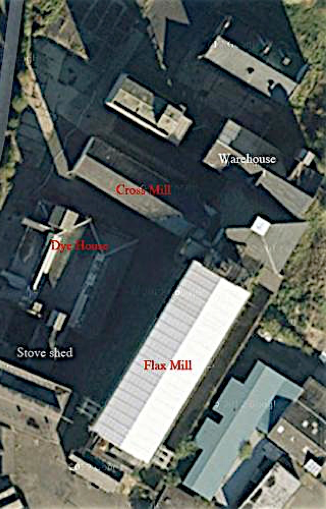

The Warehouse, Cross Mill, Dye House, Stove house and Flax Mill.

The Flax Mill is covered with scaffolding and tarpaulin

Ditherington Flax Mill Fly over link to YouTube

The Cross Mill 1812 Grade I

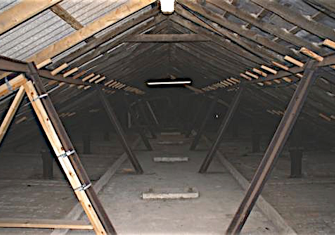

The original 1803 building burned down and was replaced with an iron frame structure four storeys tall plus an attic.. The roof however is timber without any masonry protection as was used in the Flax Mill. It is the eighth oldest iron-frame building in the World.

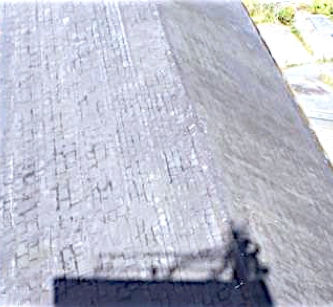

The north slope of the present roof has been Turnerised * over tally (single size) slates on felt underlay on sawn battens on timber rafters. The underlay means it was re-slated comparatively recently.

The south slope is also Turnerised but the slating is onto diagonally laid, sawn boards. The timber rafters are notched onto fish belly purlins - the latter similar to those at Abbey Mills North Mill. Judging from the ghost pattern showing through the Turnerising the lower two-thirds of the slope is covered with large random slates and the upper third with smaller tally slates.

* Turnerised - covered in hessian and bitumen.

-

-Top. The Flax Mill roof.

-

-Centre. Slating on slater’s felt on boards on rafters on brick jack arches.

-

-Bottom. Ton slates from the Cambrian slate quarries of western Gwynedd - possibly from Penrhyn Quarry. Each slope discharges to a cast iron gutter.

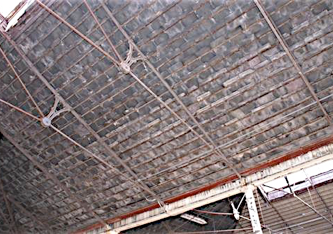

A jack arch and the iron beams and pillars

which support the roof structure

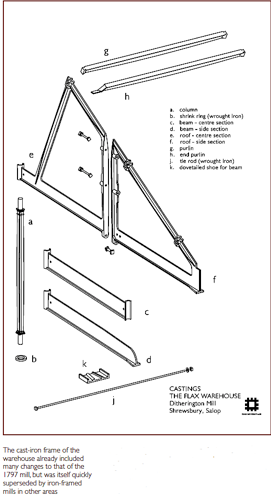

The Flax Warehouse 1805 Grade I

This four storey plus attic building is the third oldest iron-framed building in the World. The construction and slating are essentially the same as the Cross Mill north slope - slates on sawn battens on sawn rafters on iron purlins and trusses but without underlay. The truss forms in the two buildings are similar but the connections between members are different.

The slating has deteriorated and on the south slope there are many slate repairs with copper wire which predate the Turnerising. The north slope has been replaced with profiled sheeting.

Large random slates under Turnerising

The Main Flax Mill 1796-7 Grade I

The main mill had five floors including an attic and had a working area of 2,880 square metres. Its cast-iron construction was its most important feature. A local writer reported ‘The buildings are very extensive, and are secured from the ravages of fire by the exclusion of timber from almost every part of their construction, the roofs and floors are supported on brick vaults.’

The construction of the Flax Mill roof is not what came to be known as cast iron fire-proofing. Rather, it is of conventional construction of slating laid on boards on rafters. But it is protected from fire by being laid on brick jack arches supported on cast iron pillars and beams.* This is the same fire proof construction as each of the floors but in the roof the jack arching is higher to provide the falls for the slating. Drainage is provided by transverse cast iron gutters between each pair of slopes.

The roof has been extensively re-slated with tally (single size) slates replacing large random (ton) slates on many of the slopes. Slater’s felt has been introduced but would not have been included in the original roof.

* The technique of protecting timber floors or roofs by constructing them over masonry or mass concrete was often adopted. See also The Development of Fireproof Construction in Great Britain and the United States in the Nineteenth Century Sarah Wormiel Construction History Vol. 9. 1993

The Dye House and Store - various dates. Grade II*

This single storey building with later inserted mezzanine floor is roof with a decorative cast iron structure. The light-weight trusses support iron laths directly to which slates are attached with wire. The laths are set into tight fitting slots in the trusses without wedges as at Darley Abby North Mill.

The slating has deteriorated due to rusting of the wire ties and the iron laths and has been covered in part with polymer membrane. The east slope has been replaced with profiled sheeting.

Chronology

-

-1779 World’s first iron bridge

-

-1796-7 Main Flax Mill

-

-1803 Original Cross Mill

-

-1805 Warehouse

-

-1811 Cross Mill burns down

-

-1812 New Cross Mill

-

-1850 Dye House rebuilt

North slope

North slope

South slope

The outline of the large random sized slates can be seen through the Turnerising below the smaller tally slates

Slating to sawn battens and rafters

Truss sections bolted together

Jack arches forming the floor

The Stove and Drying Shed 1804, 1845, post 1855 Grade II*

The construction and slating is the same as that on the Warehouse built one year later: slates on sawn battens on sawn rafters on cast iron purlins and sectional trusses. The slates are large random sized. They are torched and have been Turnerised.

The tower above is tally slated onto diagonal boarding - bottom right image.

10/9/12

Entry on English Heritage Buildings at Risk Register

Former Ditherington Flax Mill and attached former malt kiln, Spring Gardens, Ditherington, Shrewsbury, Shropshire (UA)

Former flax mill, five storeys, built 1797 as first iron frame structure in world. Converted to maltings 1897. EH is working in partnership with the Local Authority and the Homes and Communities Agency. A masterplan for the site now has planning permission. A Heritage Lottery Fund development grant has been awarded to take forward the first phase of repair. The Friends group is flourishing.

Links to other fire proof roofs