PAPPLEWICK PUMPING STATION

10/9/12

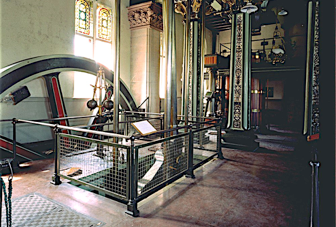

The grade II* 1881 Papplewick Pumping Station was designed by M. O. Tarbotton for Nottingham Corporation Water Department. (13 and 14) with advise from Thomas Hawksley the nineteenth century water engineer. In all he designed 150 water works for towns in Britain, Sweden, Germany and Barbados. Papplewick was part of the Trent water supply system for Nottingham.

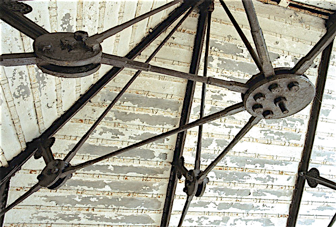

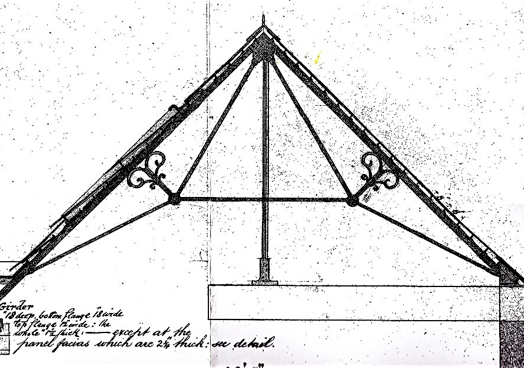

The Bolton and Watt beam engine (15) was powered by six coal-fired Galloway boilers (16) under the three roofs seen to the west of the pumping house. Because of the risk of fire from the boilers the roof was constructed with slates fixed to angle iron on inverted tee cast iron rafters (17) riveted to triangulated iron roof trusses (18). The three roofs were joined internally with wide cast iron gutters and all external gutters were lead lined into carved stone including the steps. Externally the hip and ridge cappings and finials (19 and 20) were cast iron - standard designs manufactured by Macfarlane's Saracen Foundry of Glasgow.

Papplewick slating specification

External links

13 The pumping house and reservoir *

14 The boiler house roofs are to the right of the main building

15 Inside the pumping house

16 The six boilers

18 The angle iron laths can be seen above the truss

17 The laths riveted to the rafter with the nails to the left

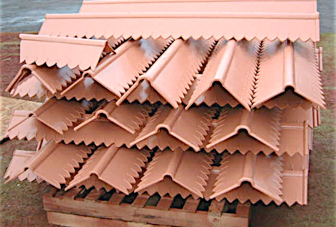

19 and 20 cast iron ridges and finials *

The slating specification of the boiler house was for Best Blue Welsh slates size 18 x 10 inches (21) with two bands of two courses of green Eureka slates (a quarry in the Nantlle valley Gwynedd) all centre fixed with lead nails which had a head to prevent them being pulled through the slates when they were being fixed. Because the top edge of the slate only sits on the narrow edge of the angle iron (22 - 24) it has to be placed further up than normal for slating. This means that sometimes the lead strap which holds the next slate above passes through the head of the slate below as well. After feeding the strap through the two slates it was pulled tight and wrapped under and round the angle. The slates were then completely torched from the inside to stop the slates from moving and also as a fire break.

The engine house roof had a similar specification but the slating was conventional - slates nailed to boarding.

During 2003 - 2007 the whole station was restored with much of the roof stripped and re-slated.

22 The slates rest on the edge of the angle iron laths

21 Slates in place and showing the lead nail heads

24 The lead nails unwrapped. Scale 25 mm

23 Slates removed to inspect the laths. Some torching still in place

25 Lead nails about four inch (100 mm) long

26 Renewed torching *

27 and 28 Finished engine house slating *

The boiler house roof

Images marked * reproduced with the permission of Papplewick Pumping Station Association

Links to other fire proof roofs