THE TAXONOMY OF ROOFING

16/5/13

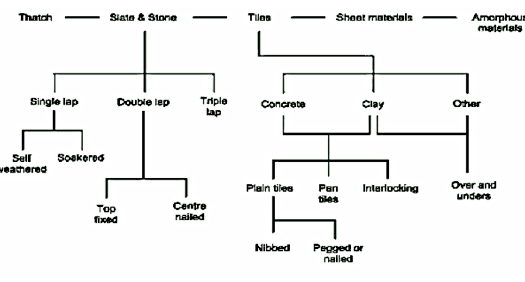

Roofing systems can be classified in two ways. The materials they are made of and the way they keep out rain. The properties of the former largely determine the techniques of the latter.

MATERIALS

They are

-vegetable or mineral

-rigid, flexible, mouldable or malleable.

-individually very small, small, large or amorphous.

Vegetable means thatch. Thatch elements are very small and semi ridged. They rely on water being passed from piece to piece downwards and out of the roof. To work they need to be assembled in thick layers and arranged at an angle that ensures that as water gradually sinks vertically through the layers under gravity it will also be carried by surface tension along the elements towards the roof surface and will have arrived at the eaves and out of the building before it can sink into it.

Slates are ridged small elements. Historically they are metamorphic stones - schists, slates, phylites, or sedimentary rocks - limestones and sandstones mainly. Today, however the term slate can also include (incorrectly) many modern materials. They are laid with sufficiently large overlaps to prevent leaks through their joints.

More about roofing stones on Slate taxonomy >

The key difference between the historic and modern slates is that the stones are simply fashioned into roughly rectangular, thin pieces whereas manufacture of the modern ‘slates’ involve breaking (crushing) basic materials into small pieces - aggregates - and reassembling them by casting, extruding or moulding them, into slate shapes. Examples of aggregates include sand, stone, slate, even rubber, and they rely on a matrix to bind them together. The matrix can be cement or resin (plastic) and it is the properties of this which determines the strength and durability of the product.

Tiles are also ridged, small elements. They are made of clay, concrete and iron and in principle could be made of any durable, mouldable material. They take four main forms: plain - similar to slates in shape and how they work; under and overs; pan tiles which are curved so that they overlap vertically and laterally (in effect under and overs combined into one tile) and interlocking which also overlap in both directions.

Sheet materials are large elements. They are either ridged and usually corrugated with vertical and horizontal overlaps; or flexible and laid in large panels with the joints welded or stuck together to make them water tight - mineral felts or elastomers - or malleable and installed with raised seams to prevent leaks - lead, copper, zinc, steel.

Amorphous materials as roof coverings are the largest of all. They form a single element covering the whole roof without joints. Examples are concrete and asphalt.

ROOFING SYSTEMS

WEATHERING METHODS

The key feature of roofs is not what they are made of but how they are arranged so that water cannot get through them and into the building. There are three methods:

-

1.making the roof covering as large as the roof so there are no joints

-

2.overlapping the individual pieces so that any water which gets through them is directed back onto the roof surface

-

3.raising the joints to take them away from the water and by forming overlaps or interlocks to prevent its penetration

-

1 LARGE ROOF COVERINGS

-

-

No joints If the roof covering is as as large as the roof there will be no leaks. This is how amorphous materials like mass concrete and asphalt work. And, as in the small winding house of the water balance at Penrhyn quarry shown here, a slate roof can be jointless too.

Double lap is the method used for plain tiles and most slatiing

-

Near to quarries very large slabs which would not survive transporting long distances are used for roofs. The are often laid single lap with joints sealed with mortar or weathered with stone cover ‘flashings’ (see single lap).

-

Sealed joints In membrane roofs the large sheets are sealed at the joints so that the roof covering is a single piece.

-

2. LAPPING SYSTEMS

-

-

Slate lapping takes four main forms: single, double and triple and, rarely in the UK, diamond. These are explained here.

Diamond pattern has been used in the past for concrete and stone-slates and is still available for asbestos cement

Thatch is pervious but relies on surface tension to track the water along the individual stems and back out onto the roof surface. The roof pitch and the angle of the thatch are critical in how it works.

3 RAISED JOINTS

Raised side laps The alternative to simple lapping is to raise the side overlaps so that water cannot reach them. This system applies to many tiles and all rigid and malleable sheet materials. Most of the tile systems have a simple head lap but some include a vertical interlock or water bar. (Leadwork Greenough Roofing)

Pan tiles Made in clay and concrete, pan tiles have an S shape in section and overlap sideways and vertically. To avoid an extra layer at the side overlap they have their top right and bottom left corners mitred. Besides the traditional S shape profile they are now available as double width. They are also made with interlocks and water bars for use at lower pitches than the traditional forms. (Image © David Lally).

Roman tiles These work in the same way as pan tiles by having a raised, curved side overlap but the pan is flat. They may be single or double width and with or without interlocks and water bars.

Interlocking tiles Any tile or even thick natural slates can have mating profiles or simple upstands incorporated into the surfaces to prevent water penetration. They are used in flat tiles (incorrectly called slates) and pan tiles with many profiles both novel and imitating traditional patterns.

Fully supported sheets All metal sheet materials are weathered by forming raised seams either self supporting in the case of copper, zinc and steel, or supported on wooden formers for lead.

Overs and unders Tiles laid in overlapping pairs known as tegula & imbrex. Carter’s patent cast iron tiles are overs and unders.

Profiled sheets are in effect very large pan tiles but are also profiled in the ‘pan’ to be self supporting. They are mitred at the corners in the same way as tiles

-

Amorphous materials Materials such as mass concrete and asphalt do not have joints so they only leak if they crack.