PYRITE

9/5/15

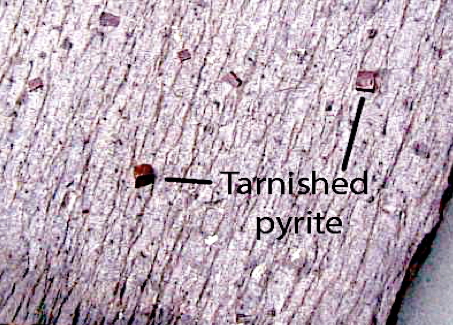

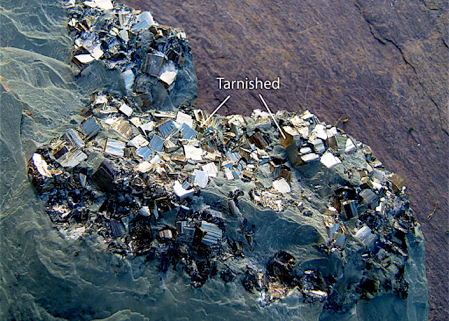

T1 slate from Easdale Island Scotland. The cubic crystals which when exposed are a bright brassy colour have oxidised but the mineral and the slate is otherwise unaffected. Suitable for roofing.

T2 slates staining the roof

T2 slates staining the roof

Slates with blisters and breakage which do not conform to the standard’s requirements

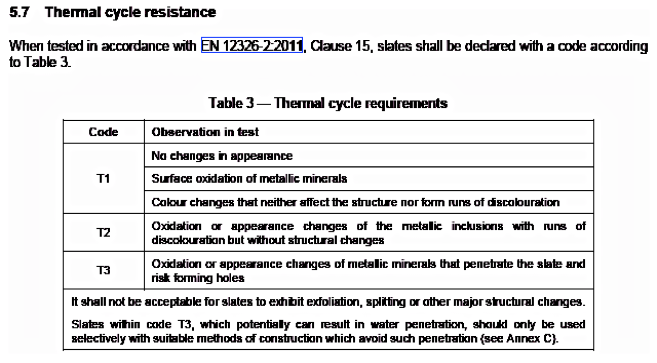

The British and European standard for roofing slates BS EN12326-2 (see below) includes controls for oxidising metallic minerals commonly known as pyrite. To conform to the standard and to be acceptable for roofing, slates must fall into one three categories T1, T2 or T3 when subjected to the thermal cycle test in BS EN 12326-2. The test involves exposing slate specimens to 20 cycles of soaking in water and drying in an oven. The outcome of the test is a demonstration of whether any pyrite in the slate will oxidise progressively when exposed on a roof. This is shown by the formation of rust stains, and / or disruption of the slate’s structure.

The term oxidising metallic minerals includes several minerals of different chemical composition and physical form including pyrite, pyrrhotite and marcasite. The chemistry and structure both influence whether the mineral will oxidise.

T1 slates are suitable for use in the UK

Although T2 slates do not show structural changes such as blistering and splitting they cause serious discolouration on the roof. This can reduce a building’s value.

T3 slates in which holes are produced when tested were formerly specially selected in France. They are not suitable for use in the UK.

BS EN 12326

In July 2004 a European standard for roofing slates was published - BS EN 12326-1: 2004 Slate and stone products for discontinuous roofing - Part 1 Product specification. This standard replaces all previous standards throughout Europe including BS680 Roofing slates. It was revised and reissued in 2014.

The product specification is mainly established against a series of tests described in BS EN 12326-2: 2011 Slate and stone products for discontinuous roofing - Part 2 Methods of test.

Any manufacturer claiming conformity with the product specification must carry out the tests (relevant to their product) described in Part 2 and make the results available in a prescribed format. This report (the official terminology is 'accompanying commercial document' ACD) is in two parts. The first part includes information about the manufacturer (producer), the slate source and the testing together with the test results. The second part explains the meaning of the tests and what is required for conformity to the standard. It is included because some of the tests have different levels of conformity (indicated by a code: S1, T3 etc) and others have varying requirements depending on the fundamental properties of the product. One example of the latter is the minimum thickness of the slates in relation to the strength of the slate rock from which they are made. It is included to help specifiers and purchasers to understand what they need from a slate and to ensure they get it. The ACD is not complete without both parts.

Because the standard contains several different levels of conformity which relate to the different durabilities acceptable in different countries and methods of slating, contractual specifications for roofing slates will need to be more sophisticated than in the past. It is no longer sufficient to specify ‘slates which conform to the relevant British Standard’ or even ‘slates which conform to BSEN12326-1’. Such blanket specifications would allow slates to be supplied at the lowest conformity level within the standard and this could mean a life of perhaps only 40 years.

A manufacturer claiming conformity to the standard should supply a copy of the ACD with every consignment.

For a full understanding of the product specification and the test methods you should read the standards. Copies are available from national standards organisations. In the UK contact BSI or their agents. On the BSI website search for 12326-1 or -2.

Other advice and controls on oxidising minerals

The National Federation of Roofing Contractors has published guidance on selecting roofing slates for use in the UK. It includes a classification of slates in relation to the BS EN12326 tests and advises that -

There have been many disputes concerning slates which have developed pyrite staining or carbonate whitening and the value of properties reduced. Anyone supplying or fixing slates classified as T2 or with a greater than 20% carbonate content is strongly recommended to inform the specifier, developer, main contractor, property owner and their agents of the likely consequence of fixing such slates.

The NHBC has published guidance on roofing slates for new build houses entitled No More Grey Areas. It permits the use of only T1 slates.